Type of

ozone generating process:

HFCD - High Frequency Corona Discharge - the most challenging and

the most rewarding ozone producing process currently known and commercially

used. The development of our HFCD systems was allowed by advancements in

the production of semiconductors, leaving classic ozone generating processes

- Low Frequency (50 and 60Hz) Corona Discharge and Cold Plasma systems far

behind. Ozone gas is produced by high voltage discharge harnessed inside

a specially designed electrode. Variable frequency of the discharge (GE ozone

generators operate in range of 0-10kHz) allows production of highly concentrated

ozone gas while maintaining precision of the ozone production.

HFCD offers

an excellent ozone output : size / weight ratio allowing the

production of smaller & lighter ozone generators with higher & more

precise ozone output and lower power consumption.

Materials

used:

All parts and components of our ozonation equipment for Ultra Pure Applications

exposed directly to the ozone stream are ozone resistant. In order to minimize

the possibility for the contamination of the ozone stream, we created a design

which utilizes only two highly ozone resistant materials for components exposed

to ozone gas:

- glass -

ozone producing cell, panel fittings, diffuser, moisturizing containers,

mixers, etc.

- silicone

- all flexible ozone lines

NO stainless

steel, low grade plastic or ceramic is used. To cope with special needs

resulting from uncompromising GE design we had to establish a glassblowing

department in our company, therefore the quality of all glass components

can be easily monitored .

Plastic Quick

connectors used for all external tubing connections were tested (85 µg/ml

for more than 5000 hours) for resistance to ozone with no sign of deterioration.

Generator

cabinet design: Generator

cabinet design:

The cabinet is a lightweight, durable, aluminum box with an industrial grade

powdercoat finish. The GE30 & GE60 Ozone Generators can be inserted into

foam within a case, mounted on a portable stand or on a wall. Upright position

of the generator is preferable because of the ventury type flowmeter incorporated

into the front panel of the ozone generator. When in an upright position the

high voltage 100% enclosed glass electrode is also "standing" in

an upright position thereby allowing any liquid that may have entered the unit

by accident or condensation to freely drain. The special design of all system

components allows the user to operate the generator even when inserted in the

foam within the case. The ozone generator can be also operated as a desk top

unit. Ozone is produced within a 100% enclosed glass high voltage electrode

and ozone output is independently regulated by a 10 step rotary regulator located

at the front panel of the generator. A 3" fan provides sufficient cooling

for all components inside the ozone generator.

| Regulation of oxygen/ozone

flow and ozone concentration:

To allow the user of the ozonation equipment

to control the exact amount and the concentration of ozone

gas produced, all GE60 ozone generators are equipped with

two independent regulators:

- Flow regulation - flow selection is

done directly by setting the oxygen flow regulator dial

at desired setting. The built-in flowmeter located at the

front panel of the GE30 and GE60 instrument allows visual

monitoring of selected flow. GE ozone generators are produced

in the two following variations:

- FM500 - our standard model with

flowmeter range 50-500cc/min

- FM100 - optional model available

upon request. Flow meter range 10-100cc/min

- Ozone concentration regulation - 10

step frequency regulator built into the front panel of

each GE ozone generator controls the frequency of the high

voltage discharge in the ozone producing cell, consequently

regulating the concentration of ozone gas produced.

|

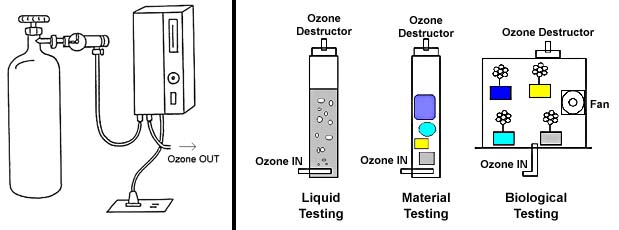

|

- Oxygen Tank

- Oxygen Flow Regulator

- Oxygen Tubing

- GE Ozone Generator

- Power Switch

- Concentration Regulator

- Flow Meter

- Ozone Outlet

|

Ozone output:

All ozone generators are tested and calibrated separately. An Ozone

Output Test Report is provided with each system. Variations of ozone

output does not exceed ± 5% - if equipment is operated under (or close

to) following conditions:

- room temperature

20-23°C / 68-74°F

- barometric

pressure 97-103 kPa

Average

ozone output produced by standard GE ozone generators are:

Ozone Output

Testing and Ozone Output Test Reports:

It is important to realize that measuring ozone concentrations is rather tricky

task due to very unstable nature of ozone gas. The precision of measuring ozone

concentrations during the calibration process of individual instruments determines

the accuracy/precision of the Ozone Output Tests Report for each ozone generator

produced and sold by our company.

Our test reports

are obtained by way of using two Ozone Analyzers utilizing UV absorption

principle based on the Beer Lambert Law. The Ozone Analyzers are sensitive

instruments which must be regularly maintained and their performance

must be monitored. For this very reason we have adopted in 1997 the

testing process in which we do not consider the results obtained from

one monitoring device (ozone analyzer) to be valid as long as they

are not confirmed with the readings from a second independent analyzer.

From our point of view the use of two independent analyzers for calibrations

of ozone generators we supply to our clients in laboratory, medical

and research facilities is an unquestionable necessity, not a luxury

or a marketing trick as some of our competitors claim.

More

Information on how we analyze Ozone Output

Ozone Output

Tests Report (OOTR)

Data collected during ozone output calibration testing are used to produce

Ozone Output Test Report (OOTR). The OOTR is a carefully designed table, which

gives the end user of the equipment an instant access to all essential data

needed for the correct and safe operation of the ozonation equipment produced

by our company. It is important that all end users of ozone producing instruments

know how to read the OOTR and how to interpret data in the OOTR.

Safety

first - Ozone Destructor:

Ozone gas in higher concentrations has the ability to irritate the sensitive

lung tissue and eyes. The Ozone Destructor is incorporated into GE line of

ozonation systems as a very important safety device and it serves for a proper

elimination of the excess ozone gas which may be produced during the start

up of the ozonation system, ozonation of water and number of other applications.

Electrical

Safety of our clients is very important to us. For this very reason

our main products - GE30 & GE60 ozone generators are powered by

12VDC - internationally recognized safe voltage which is frequently

used for control systems in volatile industrial operations. Electrical

Safety of our clients is very important to us. For this very reason

our main products - GE30 & GE60 ozone generators are powered by

12VDC - internationally recognized safe voltage which is frequently

used for control systems in volatile industrial operations.

Open Architecture

Design - "Lego" principle:

Open architecture design had always its own add on value, therefore it is no

coincidence that Lego® rules the "toy-word".

Our GE line

of ozonation systems take also an advantage of the open architecture

design. This principle allows our company to expand the GE line of

products and attachments as needed.

The additional

benefit resulting from our design approach is the possibility for the

client to customize his/her ozonation systems in accord to his/her

specific need. Our product literature may be of an assistance during

the selection process. Clients may also request our technical assistance

via telephone or e-mail.

Leading

the crowd:

To our knowledge, our company was the first developer and producer of ozonation

systems for Ultra Pure Applications to provide an Ozone Output Test Report with

each ozone generator used for Ultra Pure Applications and to implement a combination

of:

- glass high

voltage electrode with a self draining effect

- an independent

regulation for oxygen flow and ozone concentration

- an ozone

destructor

Applications:

Due to the specific design and durability of our GE ozone generators, the equipment

is able to provide ultra pure, highly concentrated ozone gas for individual

needs, laboratories, and for a wide variety of special application where

the ozone generator is required to work in a frequent ON/OFF regime or

even continuously.

The following

simple drawing outlines three main categories of laboratory testing

utilizing ozone gas produced by our GE ozone instruments.

Installation

requirements:

- Indoor

use only - protect against excessive dust, humidity and water back-flow.

- Power surge

protectors should be used to protect GE ozone generators.

Model Coding:

|